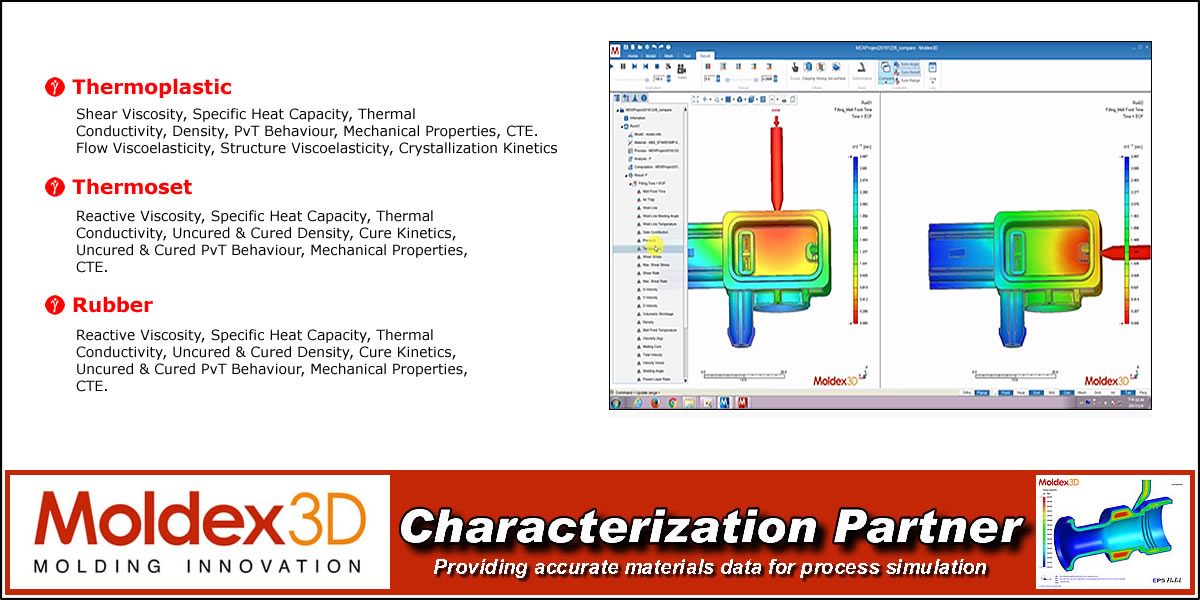

Materials Characterisation for Moldex 3D

Materials Characterisation For Flow Simulation Software

Gammadot Rheology has over three decades experience characterising both standard & novel grades of materials for injection moulding simulation trials. The company was awarded ‘Characterisation Partner‘ status by Moldex 3D in 2009 see HERE.

Thermoplastic Testing

From Virgin polymer to highly filled compounds. A full characterisation includes:

► Shear Viscosity

► Specific Heat Capacity

► Thermal Conductivity

► Density

► Transition Temperatures

►P.v.T. Behaviour

► Mechanical Properties

► Coefficient of Thermal Expansion

Thermoset Testing

From two part liquid curing systems to fibre filled dough moulding compounds. A full characterisation includes:

► Reactive Viscosity

► Cure Kinetics

► Specific Heat Capacity

► Thermal Conductivity

► Density (uncured & cured)

►P.v.T. Behaviour (uncured & cured)

► Mechanical Properties

► Coefficient of Thermal Expansion

Rubber Testing

From Liquid silicone systems to Fluoroelastomer compounds. A full characterisation includes:

► Reactive Viscosity

► Cure Kinetics

► Specific Heat Capacity

► Thermal Conductivity

► Density (uncured & cured)

►P.v.T. Behaviour (uncured & cured)

► Mechanical Properties

► Coefficient of Thermal Expansion

Already have partial data sets? If you have previously measured parameter data sets available we are happy to compile these with those measured in-house @ Gammadot Rheology to reduce the overall cost of profiling a material.