Rubber & Thermoset Cure Kinetics

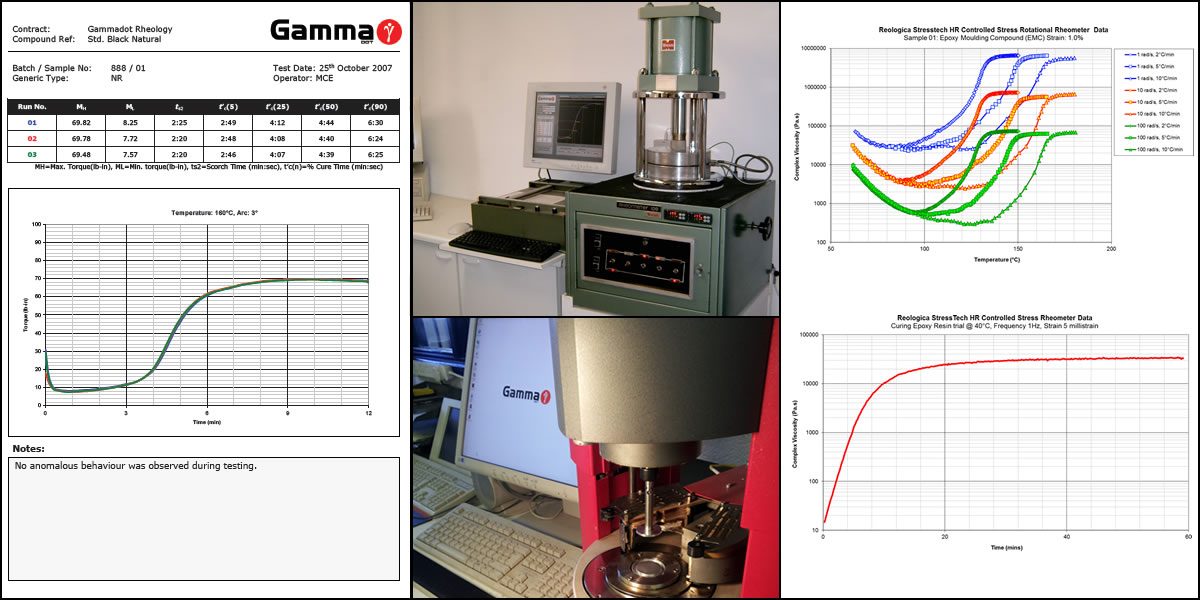

Cure Measurement utilising a Monsanto R100 Oscillating Die Rheometer

Our refurbished Monsanto R100 Oscillating Disc rheometer is utilised to provide routine Rubber cure rheometry measurements for contract testing, (for cure of other materials such as Thermosetting Plastics, Epoxies, Isocyanate adhesives, Polyurethanes, etc, see “Cure Measurement utilising a Rheologica StressTech HR Rheometer” below). The temperature control system of the machine has been completely replaced with digital temperature controllers / Platinum resistance thermometers giving temperaure control to ±0.1°C. Data is collected by a bespoke Gammadot data logger software system enabling swift analysis & comparison of data sets. Test procedures are in general accordance of the British standard: BS 903-A60.2 (ISO 3417).

Gammadot is also able to provide in-depth compound investigations utilisng an Alpha Technologies RPA2000 Rubber Process Analyzer which is available to us on a hire basis. The RPA2000 has the facility to vary both the strain & frequency applied to the rubber sample enabling the generation of comprehensive rheological information in both the pre- & post-cure state.

Cure Measurement utilising a Rheologica StressTech HR Rheometer

A major application of our StressTech HR high resolution rotational rheometer is the production of ‘Reactive Viscosity’ data for use in Autodesk Moldflow thermoset flow & cure simulations using a disposable plate measuring system.

Uncured thermoset material is tested at three constant frequencies as a function of three different heating rates. As the test progresses the sample cures and the resultant change in viscosity as cure progresses is captured. This family of 9 curves is then mathematically analysed and model parameters produced to describe the flow/cure behaviour.

The instrument has the flexibility to measure uncured materials from either liquid, paste or soft solid phase right through to the completely cured, rigid, solid phase either isothermally as a function of time or as a function of thermal ramp rate.