Materials Characterisation for Autodesk Moldflow

Materials Characterisation For Flow Simulation Software

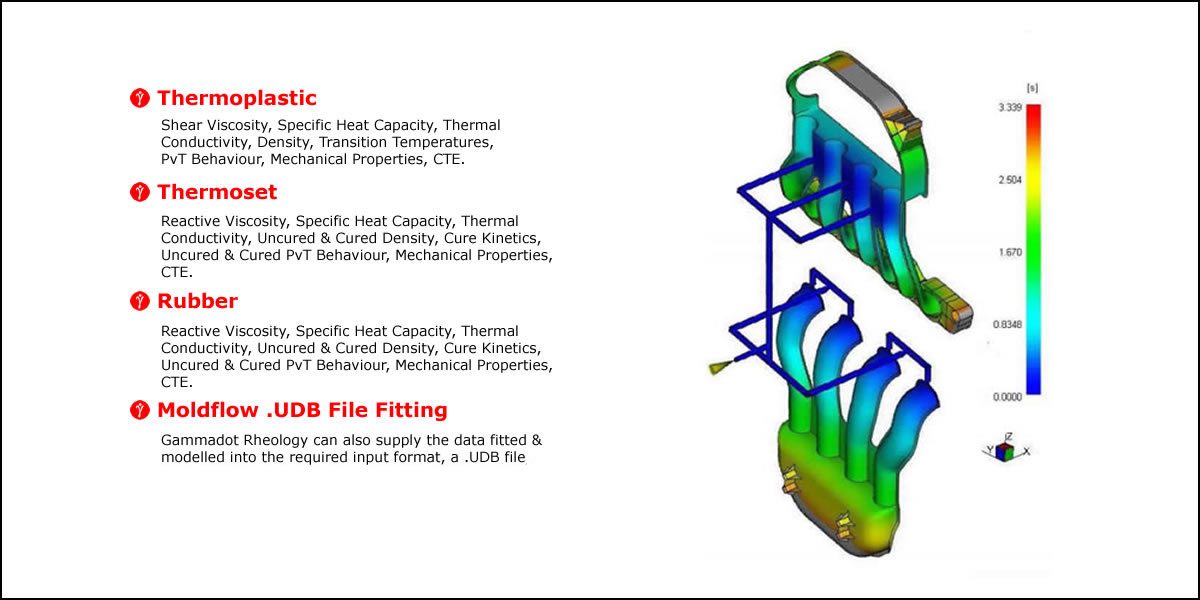

Gammadot Rheology has over three decades experience characterising both standard & novel grades of materials specifically for Moldflow injection moulding simulation trials. The past two decades has seen more focus on Thermosets & Elastomers, resulting in Gammadot Rheology becoming a global leader in the provision of characterisation services for reactive polymer Moldflow simulation.

Thermoplastic Testing

From virgin / Recycled resin to highly filled compounds. A full characterisation includes:

► Shear Viscosity

► Specific Heat Capacity

► Transition Temperatures

► Thermal Conductivity

► Density

►P.v.T. Behaviour

► Mechanical Properties*

► Coefficient of Thermal Expansion

► UDB data input file

*This does not include CRIMS (Corrected Residual In Mold Stress) testing was proprietary to Moldflow. With the closure of Moldflow labs, Australia, CRIMS data is now only available from Beaumont Technologies Inc, USA.

Thermoset Testing

From two part liquid curing systems to fibre filled dough moulding compounds. A full characterisation includes:

► Reactive Viscosity

► Cure Kinetics

► Specific Heat Capacity

► Thermal Conductivity

► Density (uncured & cured)

►P.v.T. Behaviour (uncured & cured)

► Mechanical Properties

► Coefficient of Thermal Expansion

► UDB data input file

Rubber Testing

From Liquid silicone systems to Fluoroelastomer compounds. A full characterisation includes:

► Reactive Viscosity

► Cure Kinetics

► Specific Heat Capacity

► Thermal Conductivity

► Density (uncured & cured)

►P.v.T. Behaviour (uncured & cured)

► Mechanical Properties

► Coefficient of Thermal Expansion

► UDB data input file

Already have partial data sets? If you have previously measured parameter data sets available we are happy to compile these with those measured in-house @ Gammadot Rheology to reduce the overall cost of profiling a material.