|

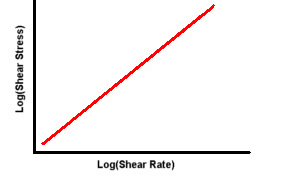

The rheological behaviour of a material is the single most important

property in the commercial processing of polymers. Fact: If the

material cannot be deformed and made to flow, you can not process

it! Many material generic types / grades have very similar flow

behaviour at low shear rate but due to structural issues such

as molecular weight / molecular weight distribution, chain branching,

polymer / filler interaction, etc, have radically different flow

characteristics at process relevant shear rates. Traditionally

many processors have relied on the Melt Flow Indexer (MFI

- or latterly known as the Melt Flow Rate, MFR) for quality control

of material pre-process flow properties.

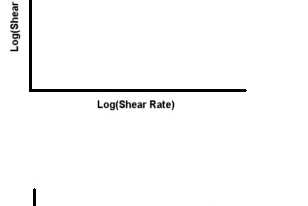

Unfortunately because the MFI is a low shear, single point test,

it is woefully inadequate at providing the full picture in relation

to process-range data. Due to the pseudoplastic behaviour of polymer

melts it is important to determine the magnitude of viscosity

across as wide a shear rate range as possible, as the material

will experience changes in flow geometries and hence shear rate

during the process. Taking a typical Polypropylene having a MFI

value of 2.4 g/10 mins (determined using a 2.16 kg applied mass

@ 230°C), assuming the density is known, an approximate shear

rate of 6.7 1/s can be calculated.¥

(It is an approximation because another failing of the MFI is

the fact that the rate is not controlled; there is an increase

in velocity as the MFI barrel empties under the constant applied

stress (load)). As most polymer processing techniques involve

shear rates of ~100 1/s up to 100,000 1/s it can be seen that

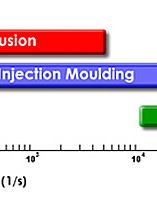

the MFI is a poor representation of the process. Figure

4 gives a visual comparison of the MFI to other polymer

processing techniques: |

| |

To

determine the shear viscosity behaviour of polymers under processing

conditions, a capillary rheometer is a fast,

accurate means of providing flow behaviour over a wide range of

shear rates at a number of temperatures and enables processing

problems such as melt fracture, die swell, etc, to be predicted

or solved offline. The data sets derived from testing can also

be modelled mathematically to provide the input coefficients required

by Finite element flow simulation software packages such as Moldflow

and Sigmasoft - to provide accurate simulations of mould filling

and packing & cooling accurate materials data is absolutely

critical.

¥Ref:

Fleming, D.J, Melt Fracture and Elongational Viscosity via Convergent

Flow Analysis , Procedings of PolymerTesting '96 , RAPRA (1996).

|

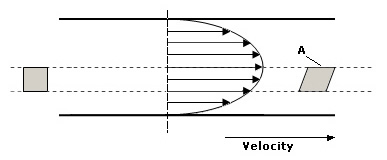

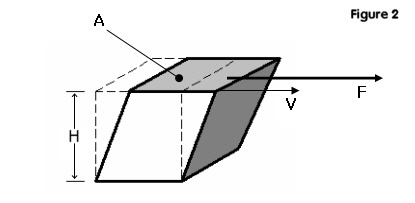

Processes

such as blow moulding, fibre spinning, film & extrusion through

complex, convergent / divergent dies lead to flow regimes where

extensional (tensile) flow dominates over simple shear flow,

Figure 5. |

Polymers with wide molecular weight distributions are extremely

sensitive to extensional flow as it is believed the longer chain

lengths retain more of the applied stresses than the shorter chains

which effects the relaxation times of the melt. A practical example

of this problem was an injection moulder producing components

which contained a central membrane with extremely narrow tolerances

(a few microns) on the wall thickness. This membrane was designed

to fracture under a specified pressure differential. Incoming

batches of material were in-house characterised prior to processing

via MFI,

but batch changes of material were still leading to sudden increases

in reject rate. MFI is primarily a single point shear flow test

and therefore unable to differentiate batches with varying molecular

weight distribution. These batches with varying molecular weight

distributions were being introduced to the process with the consequence

of, under the same processing conditions, varying relaxation times

and hence out of tolerance wall thickness leading to non-fracture

of the membrane. By changing to extensional viscosity analysis

as the pre-process quality control tool, rejects due to membrane

wall thickness variation were virtually eliminated as out of spec.

batches were apprehended and returned to the supplier.

|

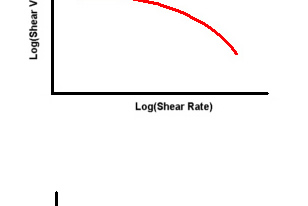

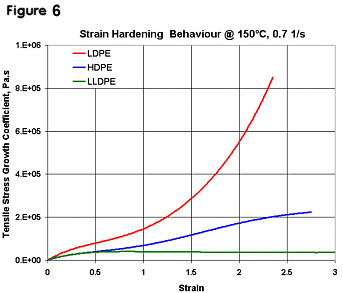

The

extensional viscosity can also increase (strain hardening) or

decrease (strain thinning) with extension rate, Figure 6.

This effect is important in fibre spinning where polymers which

exhibit strain hardening are preferred, as strain thinning would

be detrimental to the stability of the fibre and lead to dimensional

instabilities and fibre breakage.

Gammadot derive extensional viscosity data by capillary

rheometer using convergent capillary dies with 45° half

entry angles. The capillary rheometer control software has the

facility to analyse experimental using several extensional flow

models including those of Cogswell, Gibson, Rides and Binding.

|

|

|