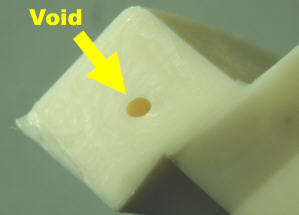

| Sink Marks & Voids |

| A

sink mark is a local surface depression that typically occurs in mouldings

with thicker sections, or at locations above ribs, bosses, and internal

fillets. A void is a vacuum bubble in the core. Causes of sink marks and voids Sink marks and voids are caused by localized shrinkage of the material at thick sections without sufficient compensation when the part is cooling. A sink mark almost always occurs in extrusion on a surface that is opposite to and adjoining a leg or rib. This occurs because of unbalanced heat removal or similar factors. Factors that lead to sink marks and voids are:

After the material on the outside has cooled and solidified, the core material starts to cool. Its shrinkage pulls the surface of the main wall inward, causing a sink mark. If the skin is rigid enough, as in engineering resins, deformation of the skin may be replaced by formation of a void in the core. |