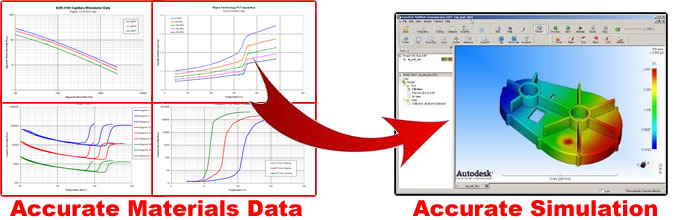

The

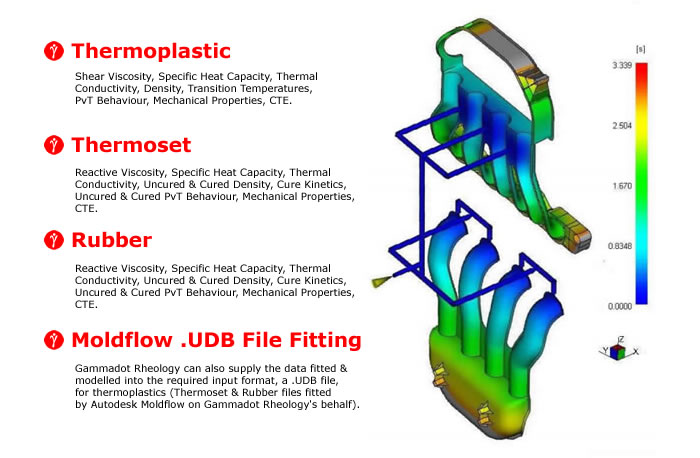

Practice of designing plastic products using computer-based finite

element flow analysis software has become increasingly

sophisticated since its conception in the late 1970’s. In order

to produce accurate predictions it is essential to use the appropriate

material properties data. Different materials, even of the same generic

type, can behave in substantially different ways during processing. Modern

software packages have material database systems that contain the necessary

characteristics on many hundreds of thermoplastic, elastomeric & thermosetting

materials, although they cannot cover every material a user is liable

to consider.

Gammadot has nearly 30 years experience characterising both standard & novel grades of materials for flow simulation trials. We offer a portfolio of testing services aimed at providing accurate materials data for a wide variety of finite element flow simulation software packages including Moldflow & Sigmasoft 3D. In September 2009 Gammadot Rheology was awarded ‘Characterisation Partner’ status for the provision of materials characterisation data for Moldex3D – the flagship true 3D flow simulation software package developed by CoreTech System Co., Ltd (Taiwan).

Gammadot has nearly 30 years experience characterising both standard & novel grades of materials for flow simulation trials. We offer a portfolio of testing services aimed at providing accurate materials data for a wide variety of finite element flow simulation software packages including Moldflow & Sigmasoft 3D. In September 2009 Gammadot Rheology was awarded ‘Characterisation Partner’ status for the provision of materials characterisation data for Moldex3D – the flagship true 3D flow simulation software package developed by CoreTech System Co., Ltd (Taiwan).