A

capillary rheometer is

in essence, a highly instrumented ram extruder

with extremely accurate ram speed & temperature control, pressure

drop measurement and capillary die geometries. For more information on

the measurement principles click HERE.

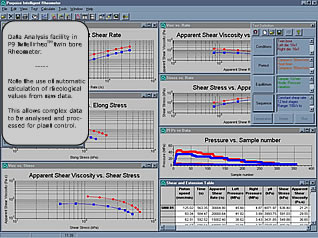

Gammadot uses

a Porpoise P9 Twin Bore Capillary Rheometer

& a Celsum Technologies ACR 2100 series

precision capillary rheometer to perform viscometry

measurements across shear / extensional rate ranges relative

to polymer processing. The rheometers are capable of measuring viscosity

data at shear rates in excess of 250,000 1/s and, in addition to providing

the required viscosity data for applications such as injection moulding

/ extrusion flow simulation, are ideal for discriminating processing problems

such as melt fracture, die swell, slippage flow, shark skinning, etc.

The instruments are fully computerised, which allows automatic testing and data collection. The data analysis systems fit routine rheological corrections, plus a large number of shear and extensional flow models, as utilised by the leading finite element flow analysis packages such as Autodesk Moldflow, Moldex3D & Sigmasoft 3D. Test methods are in general accordance of the following standards: ISO 11443-05 & ASTM 3835-02.

The instruments are fully computerised, which allows automatic testing and data collection. The data analysis systems fit routine rheological corrections, plus a large number of shear and extensional flow models, as utilised by the leading finite element flow analysis packages such as Autodesk Moldflow, Moldex3D & Sigmasoft 3D. Test methods are in general accordance of the following standards: ISO 11443-05 & ASTM 3835-02.