|

Gammadot

Rheology Testing & Consultancy Services

Unit

5C, Leaton Industrial Estate, Bomere Heath. Shrewsbury. Shropshire.

SY4 3AP. UK

Tel: +44 (0)1939 291677 ...Email: enquiries@gammadot.com

|

| |

Gammadot

Rheology Newsletter - 26 September 2011 |

Gammadot

Rheology becomes UK demonstration facility for Molecular Control

Systems Ltd with the relaunch of the Porpoise brand name.

Gammadot

Rheology has taken delivery of a technologically advanced

twin-bore capillary rheometer from Molecular Control Systems

Ltd as part of a new joint venture which sees Gammadot

become the UK demonstration site for the quality range

of rheometers produced by MCS.

The

collaboration coincides with the launch of new PRIMES

technology by MCS. PRIMES - Porpoise

- Rheometers - Melt

- Index - Expert –

System allows users of rheology, whether

it be On-line, At-line or in the Laboratory, to produce

measurements of Shear viscosity, Extensional viscosity

and Melt Index on the same platform. Direct access to

Shear Viscosity and Melt Flow information enables the

checking of product conformance to the recognized international

quality standards for polymers.

Gammadot’s

Principal, Mark Edwards said “The delivery of

the flagship P9 twin bore capillary rheometer completes

our already extensive rheometry suite, enabling us to

provide a complete spectrum of rheological measurements

– from simple Brookfield & MFI tests through

to oscillatory, shear & extensional viscosity measurements,

Gammadot has a rheometer capable of providing accurate

data to support our clients needs”.

Alan

George, Managing Director of Molecular Control Systems

Ltd will be joining Mark Edwards on the Gammadot Rheology

stand at this year’s

Interplas exhibition at the NEC,

Birmingham (Hall 4, L14), where both company heads will

be on hand to discuss with visitors the new test services

& equipment available through this recently formed

alliance.

For more information on The relaunched brand of Porpoise

rheometers, contact Molecular Control Systems Ltd through

their website HERE.

|

|

|

Back

to Top

| Come

Visit Us in Hall 4, Stand L14 This Week! |

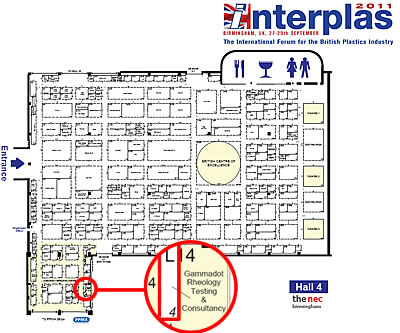

Tomorrow sees the doors open on this year's Interplas exhibition

at the NEC, birmingham and we'd love to see you there! As

mentioned above, Mark Edwards Principal of Gammadot Rheology

will be joined by Alan George, Managing Director of MCS

Ltd, who'll be on hand for the duration of the show to discuss

the exciting new collaboration between the two companies.

As is traditional, Gammadot will giving a 10% discount on

all testing orders taken during the exhibition, so come

drop by the stand and discuss your testing needs, find out

more information about the quality range of rheometers available

from MCS Ltd, or simply pick up a free, soon to be a collectors

item Gammadot enameled pin!

|

Gammadot's

stand is the opposite side of the hall to 2008 - see

you there! |

|

|

Back

to Top

|

|

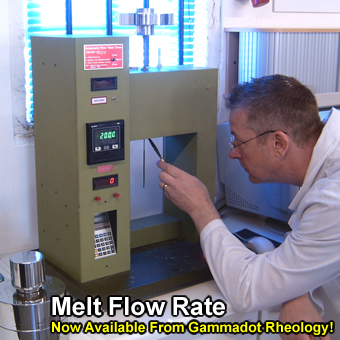

Gammadot's

Rayran Melt Flow Rate instrument is now online and performing

contract work. Measurements are made to ASTM standard D1238

method A (ISO 1133) and a full range of load weights are available

for use in measurements.

Gammadot's

Rayran Melt Flow Rate instrument is now online and performing

contract work. Measurements are made to ASTM standard D1238

method A (ISO 1133) and a full range of load weights are available

for use in measurements. |

|

| |

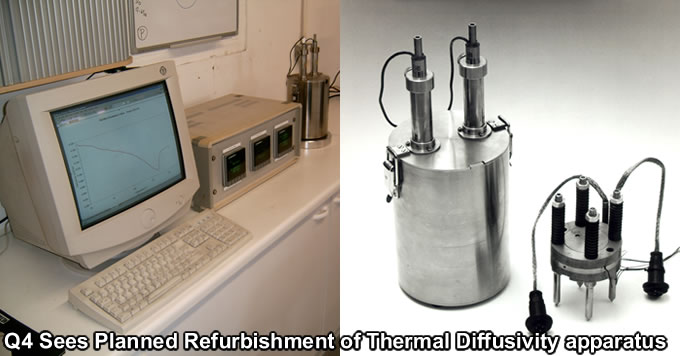

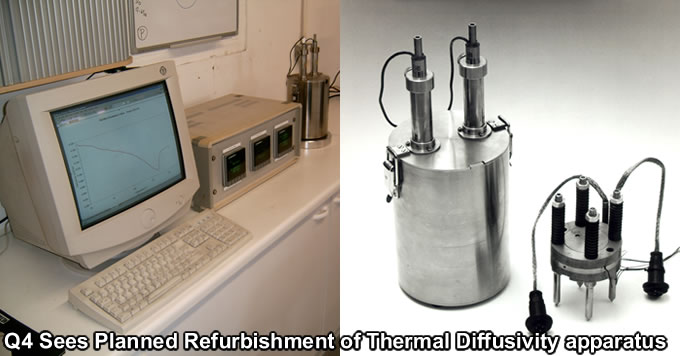

Thermal

Diffusivity Apparatus to be Revamped

|

The next few months will see the recently acquired

Thermal Diffusivity apparatus completely stripped, refurbished

& calibrated prior to becoming an intrinsic part of

Gammadot's flow simulation support suite. The apparatus

provides thermal diffusivity data across a wide temperature

range (23°C to 350°C) enabling the characterisation

of polymer heat transfer dynamics in both the solid &

melt phase. The data will also be used in conjunction

with measured PvT data & specific heat capacity to

calculate Thermal Conductivity for applications such Autodesk

Moldflow, Sigmasoft 3D & Moldex 3D.

The instrument was originally developed by Rapra Technology

Ltd and consists of a sample holder containing two disc

shaped samples, 48mm in diameter and 4mm thick. The samples

are placed together with a thermocouple sandwiched between

them for monitoring the centre temperature. The samples

are then located within the holder which is composed of

a central ring, two 'O' ring seals and two end plates,

each one of which contains a heater element. The sample

is spring loaded to allow for thermal expansion of the

samples.Two other thermocouples are sealed into grooves

in the end plates: the beads are flush with the surfaces

and thus in direct contact with the surfaces of the sample

sandwich. The thermocouples are arranged so that the three

junctions lie as closely as possible to the axis of symmetry.

During the course of a measurement the samples are allowed

to expand against springs. The increase in thickness is

measured using LVDT transducers and included in the calculations.

In use the sample holder is supported within a cylindrical

stainless steel radiation shield. Power is supplied to

the heaters and the temperature rises smoothly to a pre-selected

maximum value. The outputs from the three thermocouples

& the two LVDTs are datalogged during the test run,

and once the test terminates diffusivity is automatically

calculated by the software as a function of temperature.

|

|

Back

to Top

Gammadot

Service Flyer Download

|

|

For

further information about Gammadot Rheology's testing & consultancy

services, or if you have a specific problem / testing requirement

which you would like Gammadot to provide a solution to, please

contact us using the details at the top of the page or via the

enquiry form HERE.

You

have received this newsletter as a past customer, contact or because

Gammadot Rheology believes you are a company which may benefit

from our services, If you DO NOT

wish to receive any further email correspondence from Gammadot,

please reply to this message with the word REMOVE

in the subject bar, and we apologise for any inconvenience caused.

|

|