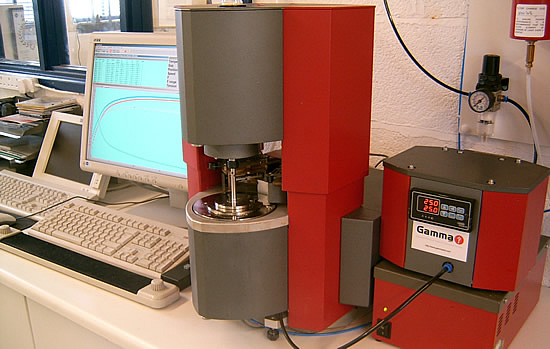

Gammadot

is establishing a new Centre for Cure. This has at its core, existing

instrumentation such as the refurbished Monsanto R100 Oscillating

Disc Rheometer and the Reologica ViscoTech Controlled Stress Rheometer

(with disposable sample plates), alongside the latest instrumentation

from Polymatrix Ltd – the PM340 Series Phase Shift Curemeter.

Gammadot was selected by Polymatrix to assist in the development

of this instrument and has become the first test house to have

a unit on site.

The

R100 ODR is, of course, the workhorse of rubber cure monitoring,

whilst the Gammadot-designed disposable plate / plate measurement

system for the Viscotech rheometer brings research-grade instrumentation

to cure-reaction studies. Together with the PM340 PSC, which

is especially suited to curing liquids, these three instruments

can provide cure monitoring for the full range of polymer types

– whether rubber or plastic, liquid or solid, flexible,

rigid or foamed.

The

PM340 PSC breaks new ground in cure monitoring in that it can

deliver state of cure in real time. There is no need to wait

until the cure is over to establish progress at an intermediate

stage. The approach also dispenses with the need to assume zero

cure at the start. Putting numbers to the initial state of cure

makes the determination of shelf life simple and routine. Indeed,

simplicity is at the heart of this new technique which seeks

to demystify cure assessment. We await your samples.

The

control of cure embraces a number of challenges – not

the least being processability in the early stages of cure.

Problems may manifest themselves in a variety of ways, and the

core instrumentation described is backed up by a host of other

characterisation techniques. These include: capillary &

rotational rheometry and Brookfield viscometry. The Centre for

Cure at Gammadot provides a comprehensive testing facility –

a true one-stop shop for problems of flow and cure.