|

Gammadot

Rheology Testing & Consultancy Services

Unit

5C, Leaton Industrial Estate, Bomere Heath. Shrewsbury. Shropshire.

SY4 3AP. UK

Tel: +44 (0)1939 291677 ...Email: enquiries@gammadot.com

|

| |

Gammadot

Rheology Bi-Annual Newsletter - March 2018 |

| Welcome

to the latest Gammadot Rheology newsletter.

This month sees the company celebrate 12 years

providing rheology & material characterisation

services to UK & international clients. As

in previous year celebrations, we've dropped our

prices on certain testing so scroll down the page

and see the savings you can make today! |

|

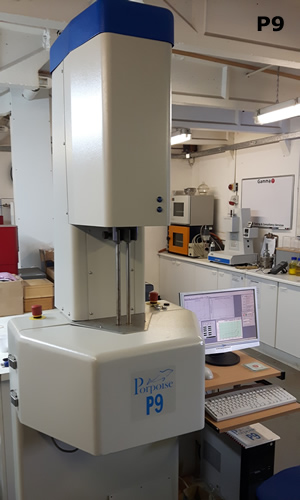

Capillary

Rheometry

- 2018 is the ACR2100 capillary rheometer's 10th year of

service and up until the supply and recent commissioning

of the Porpoise P9 twin bore capillary rheometer, (below),

was the primary method of generating high shear viscosity

data here at Gammadot Rheology. Although now superceded

by the P9, the ACR2100 is still used regularly for the measurement

of No Flow Temperature (for deriving transition temperatures

when they are unable to be determined from DSC), Melt Density

to ASTM D3835 and shear viscometry on difficult to process

materials.

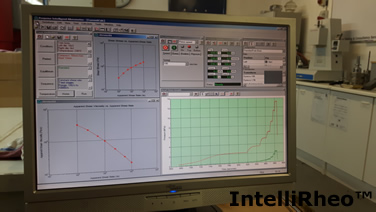

The new Porpoise P9 twin bore capillary rheometer has been

utilised for a number of projects recently producing shear

viscosity data for use in flow simulation software including

Autodesk Moldflow & Moldex 3D. It has also been useful

in providing quality control data on rubber compounds to

ensure they are within process spec. The IntelliRheo™

software accurately calculates shear & extensional data

and produces easy to manipulate output files allowing fast

processing & review of data.

Gammadot

Rheology Service Flyer Download

|

|

|

Back

to Top

|

|

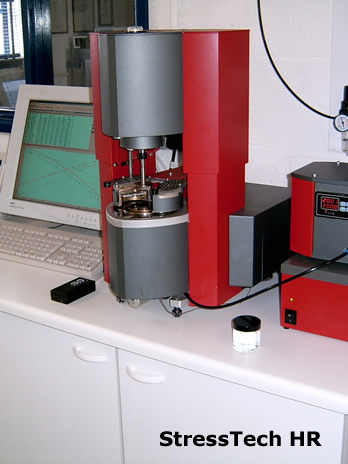

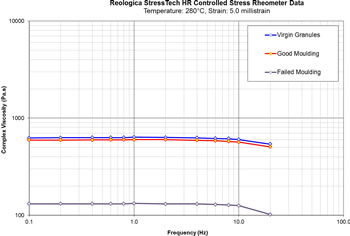

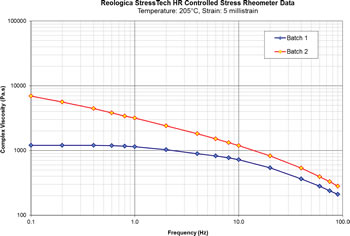

Rotational

Rheometry

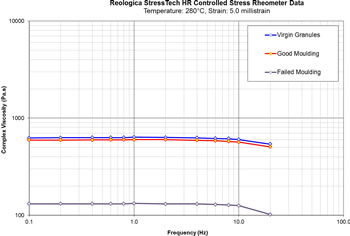

- As always, Failure analysis support has been a major

part of our rotational rheometry services this past year.

A rotational rheometer run in oscillation mode is a highly

accurate way of determining discrete (and not so discrete!)

changes in Mw & MwD caused by degradation leading

to chain scisson / cross linking of the polymer. Chain

scisson (whether it be from inadequate drying, or poor

thermal / shear optimisation of the process) can lead

to brittle failure in service and rotational rheometry

of 'good' & 'bad' product (and virgin granules as

a control if available) is a great way of determining

this.

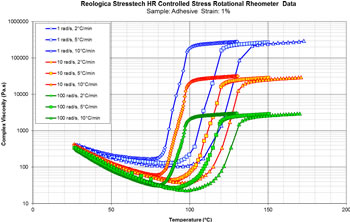

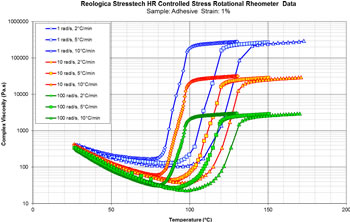

Another major application of our StressTech HR high resolution

rotational rheometer is the production of 'Reactive Viscosity'

data for use in Autodesk Moldflow thermoset flow &

cure simulations using a disposable plate measuring system.

Uncured thermoset material is tested at three constant

frequencies as a function of three different heating rates.

As the test progresses the sample cures and the resultant

change in viscosity as cure progresses is captured. This

family of 9 curves is then mathematically analysed and

model parameters produced to describe the flow/cure behaviour. |

Failure of PC Product due to inadequate drying

|

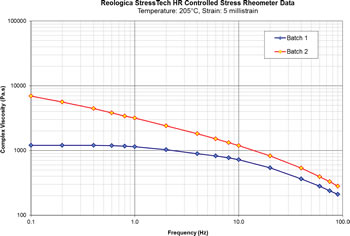

POM Production Problems due to wrong Grade

|

Reactive

Viscosity Measurements - Adhesive

|

Cure

Kinetics of PU @ Room Temperature

|

|

Rubber

quality control - testing was carried out on

the re-instrumented R100 oscillating Die Rheometer (ODR),

checking the cure characteristics of Nitrile compounds

shipped in from abroad to ensure no cure had occurred

during transit. Gammadot's R100 has refurbished digital

temperature control and bespoke data-logging & analysis

software.

|

Out

of Spec. Batch Control - The Melt Flow Rate apparatus

was utilised to discriminate out of spec. batches of material

for a client by screening out samples with excessive flow

rate values. |

PvT

Testing - A number of rubber samples (both uncured

& cured) were run over the course of two weeks. The

provision of PvT data (specific volume as a function of

pressure & temperature) is a key part of Gammadot

Rheology's flow simulation software support services -

providing data for use in Autodesk Moldflow, Moldex 3D

& Sigmasoft 3D.

|

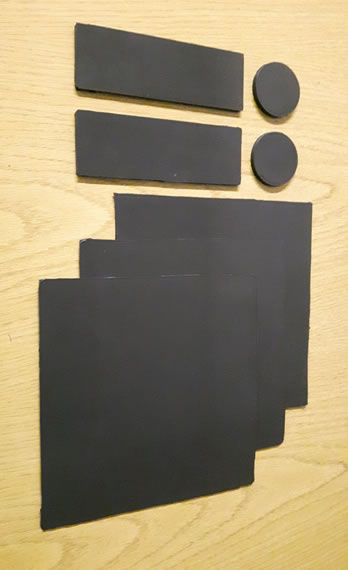

Compression Moulding Test Specimens -

A standard set of rubber test samples and sheets for stamping

test specimens out of. The various specimens are required

to perform a full Moldflow rubber characterisation.

|

|

Back

to Top

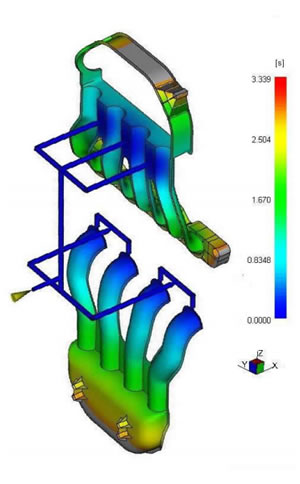

Flow

simulation Data - Mark Edwards, Gammadot Rheology's

owner and principal scientist, has been involved in supplying

material characterisation data for flow simulation packages

since 1989. As well as supplying data for use in Autodesk

Moldflow simulation of thermoplastics, rubbers & thermosets,

Gammadot Rheology can also provide data for other packages

such as Moldex 3D & Sigmasoft 3D.

|

|

|

Back

to Top

Key

Gammadot Test Services

Melt

Flow Rate

|

|

Rotational

Rheometry |

| |

|

|

|

Melt

Flow Rate (Index) / Melt Volume Rate - MFR

(MFI) / MVR to ISO standard 1133 or ASTM D1238. Full suite

of weights and both standard and half sized capillary dies

available. |

|

Rotational

Rheometry - Shear viscosity

versus shear rate / Time / Temperature • Oscillatory

Rheometry as a function of Frequency / Time / Temperature

• Cure Kinetics / Melt Stability / Thermal Degradation

Studies

to ASTM standard D4440. |

ODR

Rubber Rheometry |

|

Capillary

Rheometry |

| |

|

|

|

Rubber

Cure Rheometry - With

uprated temperature control and datalogging system. Cure Kinetics

to ISO standard 3417 or ASTM 2084. |

|

Capillary

Rheometry - Shear viscosity as a function of shear

rate • Extensional viscosity as a function of extension

rate • Melt Density to ISO standard 11443 or ASTM D3835. |

P.v.T.

Behaviour |

|

Brookfield

Viscometry |

| |

|

|

|

High

Pressure Dilatometry (PvT Behaviour) - Specific Volume

or Density as a function of temperature & pressure. |

|

Brookfield

Viscometry - LV & RV viscometer ranges available

• Full range of RV / LV spindles plus Small Sample Adaptor

(SSA) • UL Adaptor for accurate low viscosity measurements. |

Check

out our other testing services too - A variety of thermal

& mechanical testing methods are available on request.

Also, further savings can be made with volume test discounts:

6 - 10 tests = 10% discount, 11 to 15 tests = 15% discount

& 16+ tests = 25% discount! |

|

Back

to Top

|

For

further information about Gammadot Rheology's testing & consultancy

services, or if you have a specific problem / testing requirement

which you would like Gammadot to provide a solution to, please

contact us using the details at the top of the page or via the

enquiry form HERE.

You

have received this newsletter as a past customer, contact or because

Gammadot Rheology believes you are a company which may benefit

from our services, If you DO NOT

wish to receive any further email correspondence from Gammadot,

please reply to this message with the word REMOVE

in the subject bar, and we apologise for any inconvenience caused.

|

|