Dear

colleague,

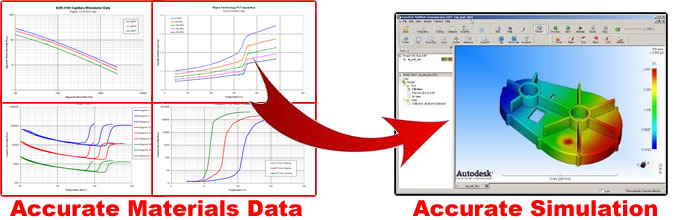

Modern

flow simulation software packages provide highly accurate models of the

injection moulding process,

but without the use of equally accurate material properties data, they

are worthless – the old adage ‘rubbish in, rubbish out‘

holds true in process simulation. For this reason Gammadot Rheology offers

comprehensive materials testing services supporting all of today’s

leading packages including Autodesk Moldflow,

Moldex 3D & Sigmasoft

3D.

Testing services range from supplying basic data for simple flow and fill

simulations through to complete packages enabling flow, fill, packing

and shrinkage & warpage analysis.

There are many different tests available to provide specific properties information for flow simulation. Below is the complete list of tests for full Moldflow analysis.

Thermoplastic |

Thermoset

/ Rubber |

Shear

Viscosity Vs Shear Rate |

Reactive

Viscosity Vs Temperature |

Specific

Heat Capacity Vs Temperature |

Specific

Heat Capacity Vs Temperature |

Ejection

& Transition Temperatures |

Cure

Kinetics |

Thermal

Conductivity |

Thermal

Conductivity |

Room

Temperature Density |

Solid

Density (Uncured & Cured) |

PvT

Behaviour |

PvT

Behaviour (Uncured & Cured) |

|

Mechanical

Properties |

Mechanical

Properties |

All tabular & graphical data is supplied in an electronic report containing testing equipment overviews and methodology. The data is also supplied in the correct .UDB file format for seamless entry into the simulation software.

|

For more information on these services or to obtain a quotation, please contact Mark Edwards on +44 (0)1939 291677 or email medwards@gammadot.com.

Gammadot

Rheology Testing & Consultancy Services Unit 5C, Leaton Industrial Estate, Bomere Heath. Shrewsbury. Shropshire. SY4 3AP. UK Tel: +44 (0)1939 291677 ...Email: enquiries@gammadot.com |